A game changer

for payments.

Quick ship Intel products.

Elo’s Quick Ship program expedites customer deliveries of

select Intel-based touchscreen computers.

Kitchen automation

you can count on.

Increase efficiency and reduce bottlenecks with Elo’s line of Kitchen Display Systems.

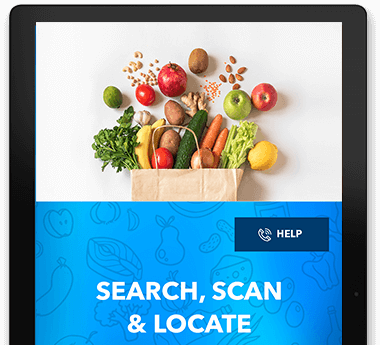

Interactive solutions for grocery stores.

Enhance the grocery shopping experience, increase customer engagement, enable self-service and promote brand loyalty with modular touchscreen solutions.

Enhance patient care

where it matters.

Streamline your healthcare administration and enhance the patient experience.

Mobility built

for enterprise.

Android mobile computers designed to support your everyday business.

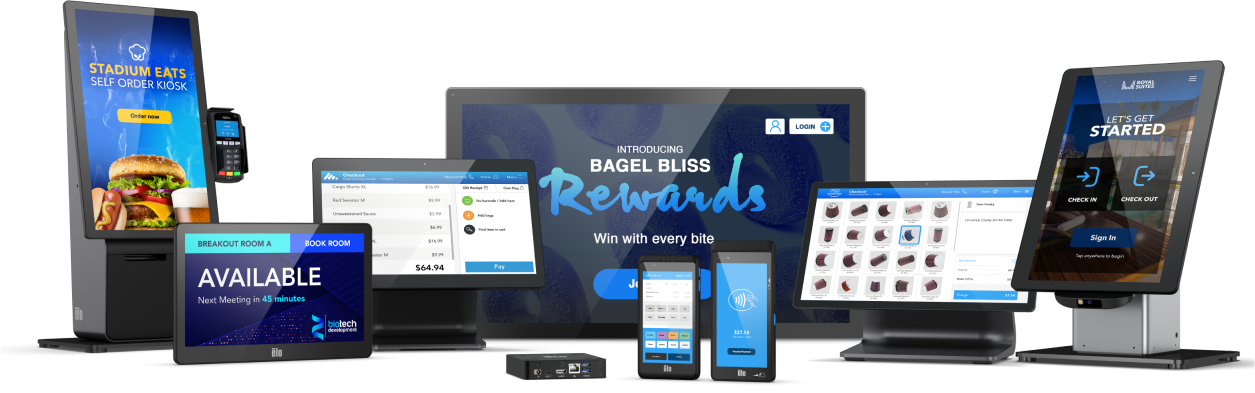

Self-service

solutions made easy.

Versatile self-service platform designed to adapt to consumers’ changing behavior.

Outdoor

Open Frames

Designed to survive the elements, Elo's weatherproof touchscreen covers you from day to night.